STK SERIES AUTOMATIC STOKER SOLID FUEL BOILERS WITH INVERTER TECHNOLOGY

DEHA 25 STK

STK SERIES AUTOMATIC STOKER SOLID FUEL BOILERS WITH INVERTER TECHNOLOGY

| HEATING POWER | 30 KW |

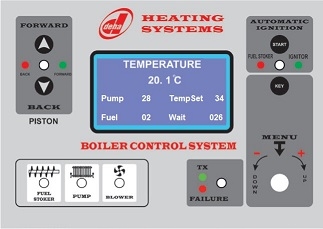

| CONTROL PANEL | With micro controller digital sensor (0,1°C sensibilty) |

| FUEL TYPE | Solid fuels sized between 5-50mm diameter |

| FUEL CAPACITY | 105 kg pellet - 175 kg coal |

| HEAT TRANSFER SURFACES | 2 cross pass between water tubes + 3 horizontal + 2 vertical pass |

| AUTOMATIC IGNITION | Electronic solid fuel ignitor (Optional) |

| CLEAN HOT WATER | Internal serpantine system for clean & hot water (Optional) / (30 mt copper pipe serpantined in water jacket of boiler) |

| ROOM THERMOSTAT | Controls and fixes temperature of room with 0,1 C° sensibilty (Optional) |

| ELECTRONIC SYSTEM | Inverter Technology |

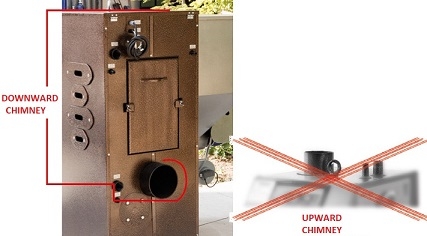

| CHIMNEY LOCATION | DOWNWARD |

INVERTER TECHNOLOGY A++ ENERGY SAVER SYSTEM

Inverter technology term which is common to hear about white appliances is begun to be used for solid fuel boiler systems by leader of this sector ^^DEHA^^. This future technology provides very less electric consumption, very silent working and so long mechanical warranty as 5 years.

DOWNWARD CHIMNEY EFFICENT SYSTEM

Other factor effected on boiler efficiency is the position of chimney outlet on boiler. Hot gases leave from chimney in boiler has stack on top without transfering heat to the boiler .Chimney temperature rises and this cause waste of fuel.

INTERNAL SERPANTINE SYSTEM FOR CLEAN & HOT WATER

Deha combine solid fuel boilers with stoker which heat your house and provide hotwater has a copper pipe serpantine system inside. As different from external hot water suppliers, internal serpantine system provides unlimited clean hot water without any energy loss. Serpantined copper inside boilers during pruduction period does not take any volume in your boiler room. Clean and hot water flows from your taps for using external use(not for drink ) as most comfortable and cheapest way. This property is provided as optionally for Transposer - Reciprocating and Huge Coal types of solid fuel boilers.

5 YEARS WARRANTY FOR MECHANIC PARTS

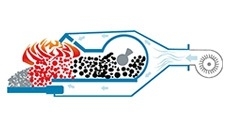

Because the system lies on horizontal axis, spiral shaft works smoothly. Burden of the coal does not make any pressure on the spiral shaft. Coal passes from large range of spaces to combustion chamber. Even a coal with 5 cm length can be transferred to combustion chamber without having any blockage. Therefore, spiral shaft, loading motor and reductor are not enforced or harmed. Problems occur in the vertical system such as accumulation of stone, dust, metal tools at the bottom do not take place in our horizontal system.

The chambers design allows it to provide an ability of cooling water. As a result of cooling by water, it stands many years without having deformation. In addition to this, heat of the chamber added is added to the system. It provides saving from fuel comsumption. The burning room surrounded by water is not deformated due to being cooled.

5 YEARS WARRANTY FOR COMBUSTION CHAMBER AND SPECIAL AUGER

AUTOMATIC IGNITION

ACCURATE ROOM THERMOSTAT

After extensive researches, DEHA engineers developed accurate room thermostad which controlls and fixes temperature of room. As diffrent from ordinary room thermostads, this invention controls the set temperature of boiler, instead of turning on and turning off boiler with a suitable prinicible of burning solid fuel. This system provides you to not to go to the boiler for adjusting set temperature of boiler to have a stable temperature in your room. Accurate temperature controll of room provides also less fuel consumption and maximum comfort. This property is provided as optionally for our Transposer-Reciprocating Series and Huge Fuel Series boilers.

NO SOOT, NO SMELL, NO SMOKE

Do you have ordinary machine or DEHA in your boiler room? With the last burning technology Deha keeps the fire on combustion chamber and not let go back to coal bunker. There is no burning , deformation, smell or smoke on stoker . Non-flammable, long-lasting seals with 350 ° C resistance on all covers ensure excellent sealing . There is no shoot, smell, residue or smoke in your boiler room. So, you can install your boiler to your car parking area and you can parking your car safely.

MICROCONTROLLED DIGITAL CONTROLLER

The Control Panel designed by using very high sensitivity (0,001°C) DIGITAL SENSOR has hardware and flexibility can burn every solid fuel. All design and development processes made at our R&D center of Digital Control Panel is let you control of boiler's confor and confidence with high stability is can not find on liquid and gas fuel boilers.